-

Began with a Basket

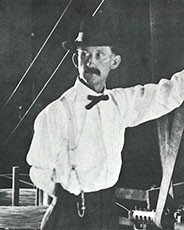

August Kaspar was a rancher, laboring from dusk to dawn on his land in South Texas. He was also a problem solver, an inventor and an innovator. When he noticed that his neighboring ranchers were discarding their steel wire fences for barbed wire fences, he took the opportunity to solve a problem of his: He needed an item that would help him carry corn shucks and hay. Sitting in the shade of a large tree on his property, August worked his hands and a pair of pliers to twist the thrown-away wire into a basket that would solve his problem. As it turned out, his neighbors had the same problem. A neighbor bought the basket for a dollar, and then another neighbor bought another basket, and just like that Kaspar Wire Works was born.

-

Sold in Stores

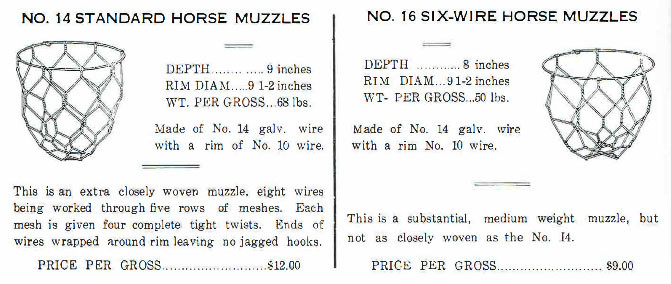

Up until this year, August had sold most of his products by loading up his wagon with hand-made baskets and horse muzzles and peddling them from farm to farm. August decided in 1902 to sell his products in stores rather than horse-and-buggy home deliveries. Starting with the Shiner-based companies C.B. Welhausen, J.C. Blohm and Wolters Bros., as well as J.T. Jaeggli in Moulton, August successfully made the switch from customer delivery to store supplier. He strengthened his in-store product presence by making numerous sales trips on the San Antonio and Aransas Pass Railway. This distribution adjustment gave August the ability to reach a wider audience across South Texas and expand his growing business venture.

-

Retired from Ranching

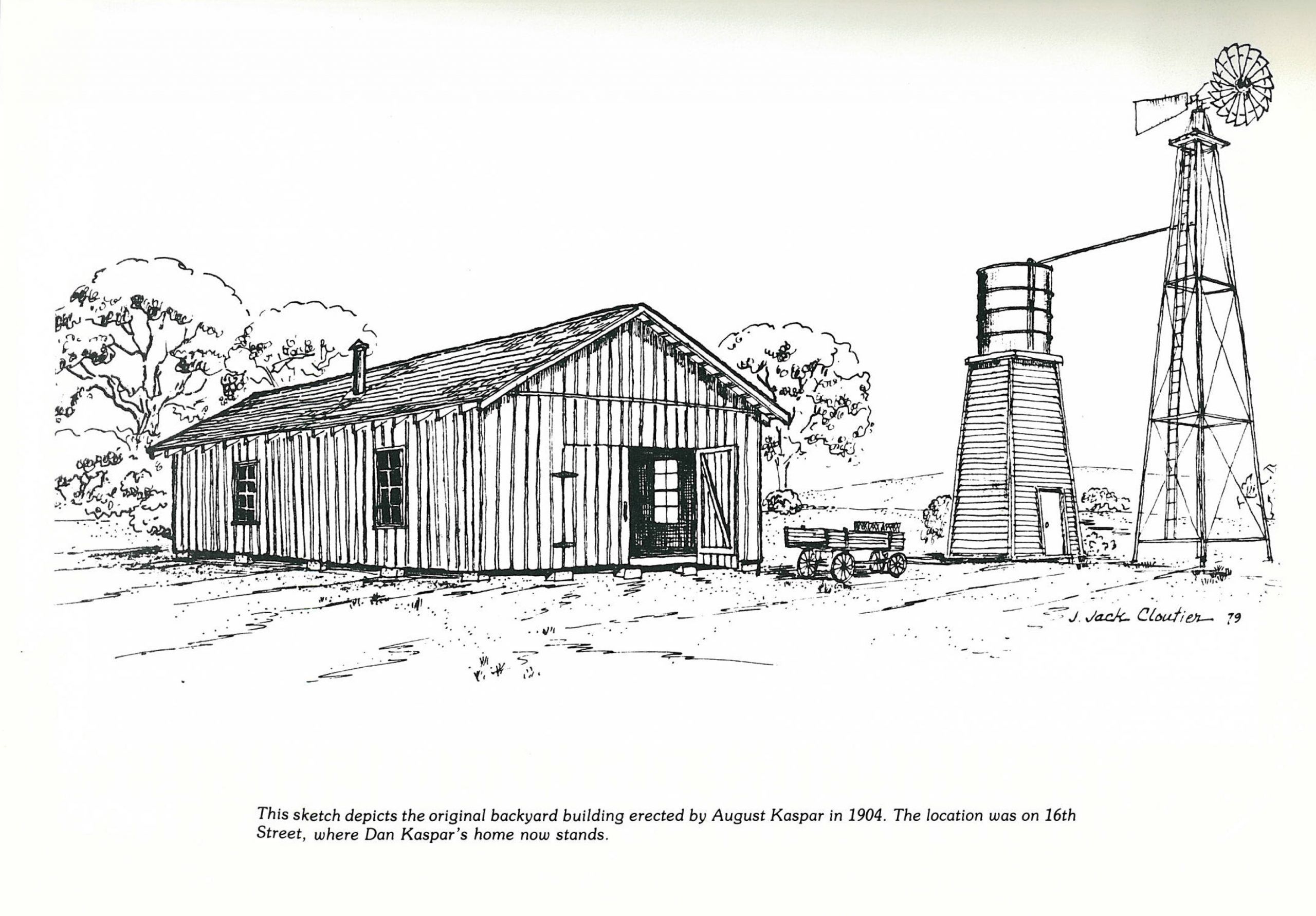

August decided to retire from ranching and focus entirely on the wire business in 1904. He sold his ranch and bought 2 acres of residential land in Shiner, Texas. Kaspar Wire Works, as it was called in this time period, was now headquartered in a wooden barn-like structure that August built by hand in his backyard. He also invested in the company’s first piece of machinery. It was a hand-cranked wire straightening and cutting machine, and the addition of straight and precisely measured wire was a major stride in quality compared to the crude and crooked wire he had been working with before.

-

Action with Automobiles

Out of August’s seven children, it was Arthur who decided to settle in Shiner and join the family wire business. Arthur, just 18 years old at the time, significantly widened the market for wire baskets and horse muzzles by purchasing the company’s first Model T Ford. With an updated method of transportation, he was able to travel to cities and states that the business had never reached before, and with samples in tow, he was able to increase sales and introduce our products to new territories.

-

Headquartered by Highway

Even though the symptoms of the Great Depression were beginning to appear in South Texas, operations at Kaspar Wire Works had officially outgrown the capacity of its first facility. Thus, the newly laid Highway 95 looked to be a promising option for the company’s relocation. Arthur purchased a few adjacent lots north of Shiner’s main town and constructed a 40-by-100 building that still stands as part of Wire Works’s headquarters more than 85 years later. Kaspar Wire Works has since developed around this original building into our current 40-acre, 550,000-square-foot manufacturing facility.

-

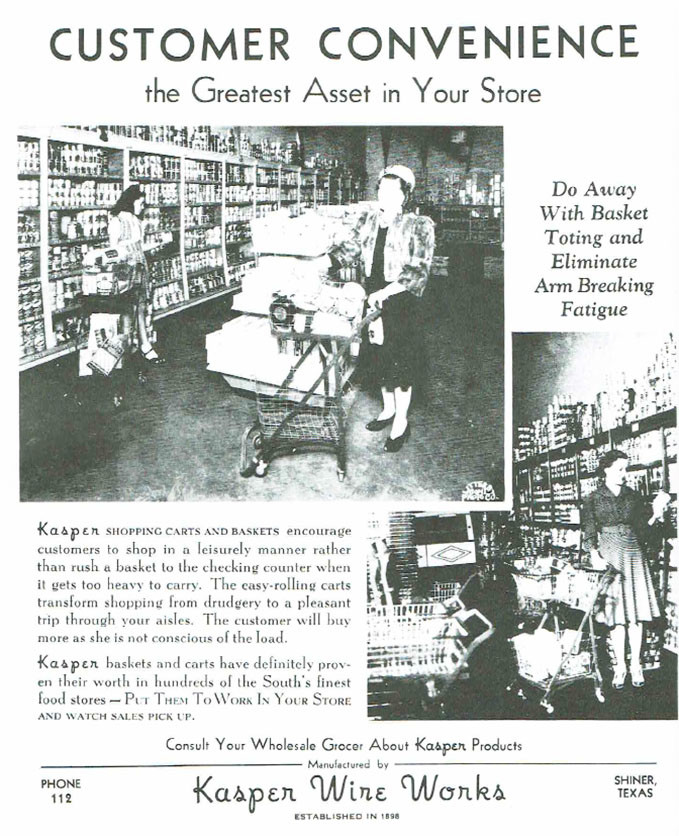

Created the Carrier

Arthur’s impeccable salesmanship and industry foresight contributed to Kaspar Wire Works’s transition into modern industries. In 1937, a brainstorming session between Arthur Kaspar and Perry Warmath resulted in the invention of the now ever-prevalent shopping cart. Perry’s wife had made the comment that carrying a basket full of groceries was an “arm-breaking” task. Since the beginning, Kaspar Wire Works’s solution-driven purpose has impacted our products, and this case was no different. After an hour of scratch-pad sketching, the two men arrived at the design of a “Basket Carrier.” It was February 4, 1937, when we sold the first ever shopping cart to a Weingarten store in Houston. From the very beginning, we marketed the revolutionary “Basket Carrier” to professionals in the up-coming industry of self-service grocery stores as a way to increase sales based on the reasoning that individuals would put more items in the cart because they no longer had to carry the weight. We were right, and as with most revolutionary ideas, a multitude of other companies made their way into the shopping cart business.

-

Humbled by Hardship

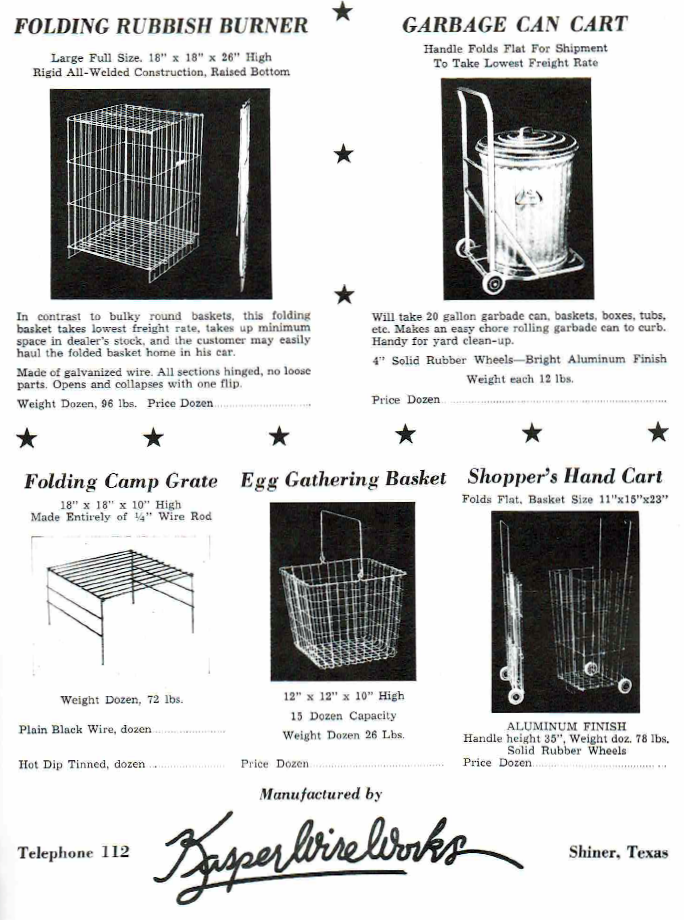

From 1941 to 1945, the United States of America was involved in World War II. While the war took a heavy toll on business at Kaspar Wire Works, we persevered and conserved our business by contributing to wartime efforts. Soon after the December 7 bombing of Pearl Harbor, we received a telegraph from the war department ceasing the production of all civilian products, which was 100 percent of our operation. We were able to quickly adapt by utilizing our facilities to manufacture necessary military hardware and components, but not in a capacity that could prevent our team members from seeking employment elsewhere. Toward the end of the war, we only had a small crew of around five people, but our production line was booming as we created a variety of baskets, carts, steel ammunition box handles, folding rubbish burners and other necessities for the war. Unfortunately, the substantial production did not translate to our financial situation, and the combination of the Great Depression and World War II left us struggling to survive. It was our ability to logically conserve and our dedication to the company that allowed us to spring back into steady operations after the conclusion of the war.

-

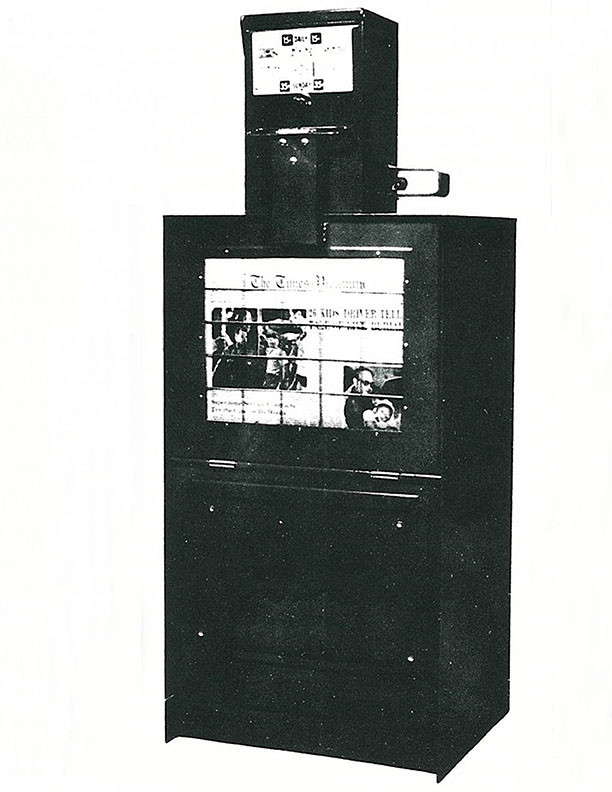

Reinvented the Rack

By 1956, Arthur’s son, Don Kaspar, had joined the family business and was working with his father to invent a solution for a problem in the newspaper industry. The racks of the time had a serious flaw: People were able to pick up a stack of newspapers without paying for them. Kaspar Wire Works set out to solve this problem, and in doing so, we invented a coin mechanism and a large capacity rack that revolutionized the newspaper rack industry. Thus, Sho-Rack, the leading newspaper rack brand throughout its 60 years of existence, came to be.

-

Harnessed the History

On November 24, 1970, an official Texas Historical Marker was dedicated to the original Kaspar Wire Works. Standing in front of our administration building in Shiner, Texas, the marker recognizes our company as a historic landmark and pays tribute to our local legacy. Don’s four boys – David, Dan, Douglas and Dennis – attended the dedication ceremony, and they would each go on to hold important roles within the family business based on their respective talents.

-

Nationalized the Newspaper

One of our most memorable Sho-Rack orders played an influential role in the historic launch of the first national newspaper. In 1982, we expedited 100,000 Sho-Rack newspaper racks for USA Today. The newspaper racks containing USA Today’s inaugural issue were installed overnight in cities all around the nation and available for purchase the following morning. The popularity of Sho-Rack’s product line significantly contributed to the adaptability of Kaspar Wire Works. To meet the growing demands of the newspaper industry, we made major expansions in operations, from continually improving our products and systems to increasing the size of our staff and facilities.

-

Enabled by Engineering

It was in 1995 when Kaspar Wire Works’s Doug Kaspar and Paul Morkovsky were introduced to electrocoagulation technology. A small Colorado engineering firm had attempted to create an electrocoagulation wastewater treatment system, and we recognized its potential as an alternative to the chemical precipitation standard of removing heavy metals from wastewater that had posed many challenges to our electroplating division. Although it failed to effectively operate, we bought the electrocoagulation system from the engineering firm and started designing a prototype that could properly function. From the moment we turned on our very first prototype, we recognized that the reactors we had designed were more effective at treating the water and more efficient at operating than those of our competitors. We named our electrocoagulation wastewater treatment system Kaselco, and after years of perfecting its processes, we sold the state-of-the-art technology in 2013 to Baker Corporation of California.

-

Transformed by Transition

The year 2007 marks our transition into the fifth generation of Kaspar family involvement. At this point, there are three generations cohesively working at the family business: Don Kaspar of the third generation, three of his sons of the fourth generation, and four members of the youngest 5th generation. The manufacturing plant spans 550,000 square feet over our 40-acre headquarters, expanding around the original “Kaspar Wire Works” building from 1930. We continue to pursue excellence in manufacturing by acquiring modern equipment and technology.

-

Revived with a Partnership

In 2023, our wire fabrication company became Marlin Steel’s Kaspar Wire Works: Marlin Steel’s Kaspar Wire Works. We have these capabilities to serve you: wire, sheet metal, machining, and milling, electroplating and painting, and engineering. With a new logo and updated website, we are re-establishing our company in preparation for our next 125 years of quality, precision, and innovation in American manufacturing.

Began with a Basket

August Kaspar was a rancher, laboring from dusk to dawn on his land in South Texas. He was also a problem solver, an inventor and an innovator. When he noticed that his neighboring ranchers were discarding their steel wire fences for barbed wire fences, he took the opportunity to solve a problem of his: He needed an item that would help him carry corn shucks and hay. Sitting in the shade of a large tree on his property, August worked his hands and a pair of pliers to twist the thrown-away wire into a basket that would solve his problem. As it turned out, his neighbors had the same problem. A neighbor bought the basket for a dollar, and then another neighbor bought another basket, and just like that Kaspar Wire Works was born.